Chemical engineers are responsible for coming up with a safe oil refinery plant. These are people who have undergone training in plant designing and some of the factors they put into consideration when designing a plant include safety, controllability and environmental constraints. Their main objective is to construct a plant that will not out the employees and the community in danger.

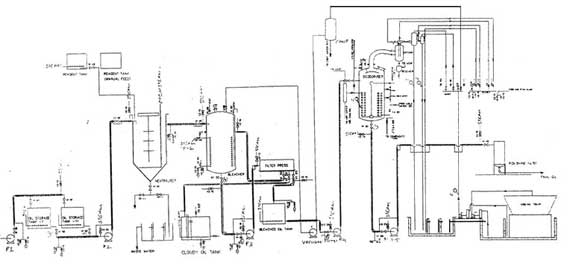

The plant design size will depend on the capacity it is expected to handle while pipes, valves and compressors are chosen based on the flow capacity they are expected to handle. The oil refinery plant may also include excess valves and pipes to handle leaks. Often, these engineers build the plant from a small plant known as a pilot study. This is a small plant and if it succeeds, the engineers will borrow ideas from it. By using a small sample, they can avoid extensive losses.

Besides chemical engineers, other engineers such as mechanical and electrical are involved to look at the mechanical and electrical details of the plant. Structural engineers, on the other hand, are used to ensure that the structure can withstand the weight of the pipes and other equipments used in the construction of the oil plant.

-

Recent Posts

Archives

Categories

- Choosing Oil Refinery Plant

- Determine Oil Refinery Plant Cost

- In Waste Oil Refinery Plant

- Oil Extraction Process

- Oil Filter Machine

- Oil Pretreatment

- Oil Refinery on Sale

- Oil Refinery Plant

- Oil Refinery Plant Design

- Oil Refinery Plant Works

- Oil Refinery Process

- Oil Refinery Products

- Olive Oil Processing

- Palm Oil Processing

- Palm Oil Refinery Plant

- Seed Press Machine

- Soybean Oil Extraction

- Types of Cooking Oil

- Uncategorized

- Vegetable Oil Refinery Plant