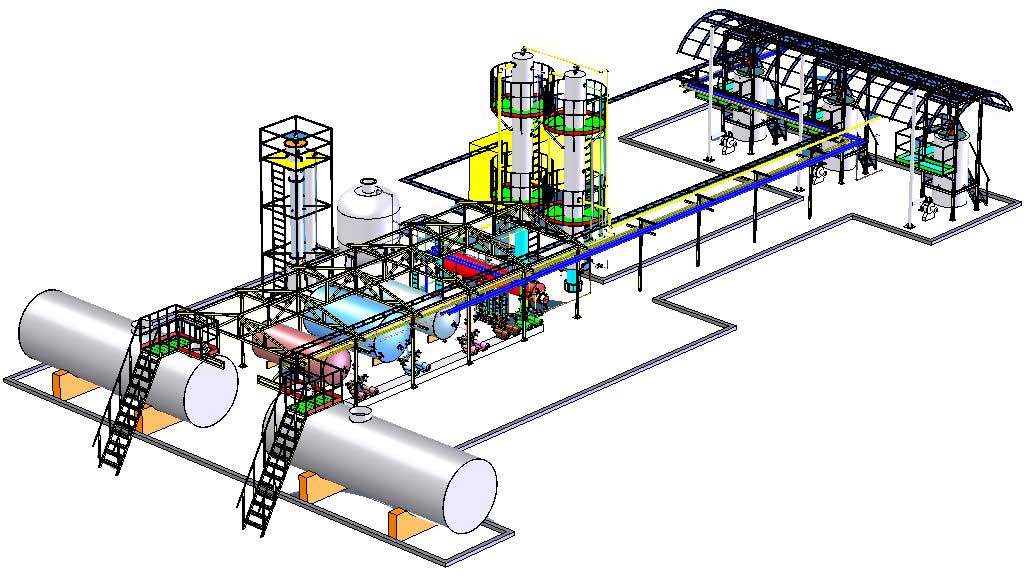

A Vegetable oil refinery plant uses vegetable oil as the main raw material. The vegetable oil is converted into fuel or vegetable oils through a process known as hydro cracking that involves breaking large molecules into smaller ones which are easy to separate. The final products include cooking oil gasoline, propane gas and diesel.

Vegetable oils can be obtained through simple mechanical extraction whereby the oil is squeezed out using a daysis screw press. A screw press can be used to extract oil from peanuts, mustard seed and canola seed and many others. This is only good for small scale but you will need a bigger plant if you are planning to extract oil in large scale. Since Hexane is used in the extraction of vegetable oils, refinery is important before the oil can be released for human consumption.

Physical impurities in vegetable oil can be removed through filtration, but a more complex process is required to remove fatty acids, coloring pigments and other impurities. A vegetable oil refinery plant involves the separation of impurities from the oils. Centrifugal separators can be used if the impurities are in small qualities. The final product of vegetable oil refinery plant is free from gums, color pigmentation, fatty acids as well as odor.

-

Recent Posts

Archives

Categories

- Choosing Oil Refinery Plant

- Determine Oil Refinery Plant Cost

- In Waste Oil Refinery Plant

- Oil Extraction Process

- Oil Filter Machine

- Oil Pretreatment

- Oil Refinery on Sale

- Oil Refinery Plant

- Oil Refinery Plant Design

- Oil Refinery Plant Works

- Oil Refinery Process

- Oil Refinery Products

- Olive Oil Processing

- Palm Oil Processing

- Palm Oil Refinery Plant

- Seed Press Machine

- Soybean Oil Extraction

- Types of Cooking Oil

- Uncategorized

- Vegetable Oil Refinery Plant