Palm oil is used in a variety of ways and is always in demand in areas such as cosmetics, food production, cleaning agents as well as an edible oil. The oil that is extracted from palm fruits is not edible at first and needs to go through a number of processes in order to be refined. The refining ensures that if there are any byproducts remaining in the oil, they are eliminated thus leaving it pure. The extraction of palm oil is not as simple as what is witnessed when extracting oil from seeds and other materials that bear oil.

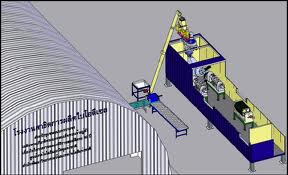

The process that the palm fruits are put through to be able to extract as much oil as possible begins with sorting. Here, the palm fruits that are not of the required quality are separated from the rest and disposed. The palm fruits that are of good quality are taken to the processing plant and are taken to another stage known as the conveyer system. At this stage the fruits are split into pieces that are much smaller before they are ushered into a cage where they are sterilized. The sterilization process removes any impurities making them ready for the rest of the production process. After sterilization, they are moved onto the threshing drum where the flesh is separated from the husks, then moved to the digesters. They are eventually placed in the presser where the extraction of the oil takes place but in a crude form.

The process that the palm fruits are put through to be able to extract as much oil as possible begins with sorting. Here, the palm fruits that are not of the required quality are separated from the rest and disposed. The palm fruits that are of good quality are taken to the processing plant and are taken to another stage known as the conveyer system. At this stage the fruits are split into pieces that are much smaller before they are ushered into a cage where they are sterilized. The sterilization process removes any impurities making them ready for the rest of the production process. After sterilization, they are moved onto the threshing drum where the flesh is separated from the husks, then moved to the digesters. They are eventually placed in the presser where the extraction of the oil takes place but in a crude form.

The crude oil is then clarified and then dried before it goes through the palm oil refinery process. The process ensures that there are no impurities in the palm oil and it can now be used in many ways without the fear of infection because of any type of contamination.